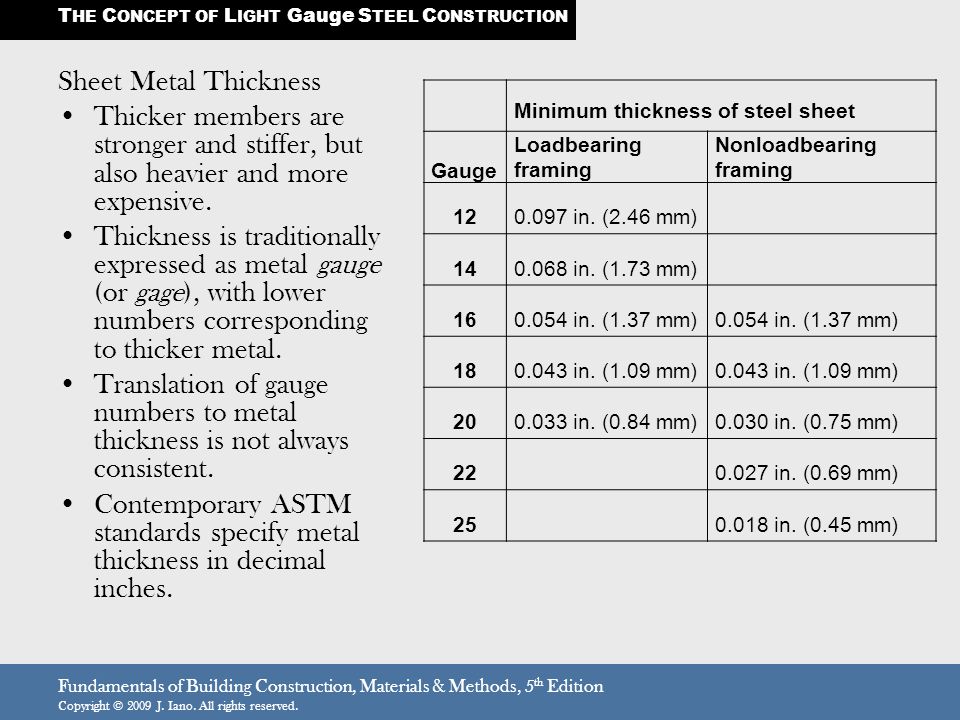

The equivalent thicknesses differ for each gauge size standard which were developed based on the weight of the sheet for a given material.

Minimum thickness of sheet metal in mm.

Sheet metal gauge thickness chart 2019 10 24t01 36 33 00 00 when working with sheet metal the term gauge is often used.

Is it possible to do tapping in 3mm thickness sheet and if not self clinching nuts pem nuts are the only way.

It has impact on sheet metal part design as well.

Elevator surfaces such as doors and cab wall facings are usually specified in 18 gauge 0 050 or 1 20 mm.

The coils are formed by running a continuous sheet of metal through a roll slitter.

Material selection is a very important part of product design.

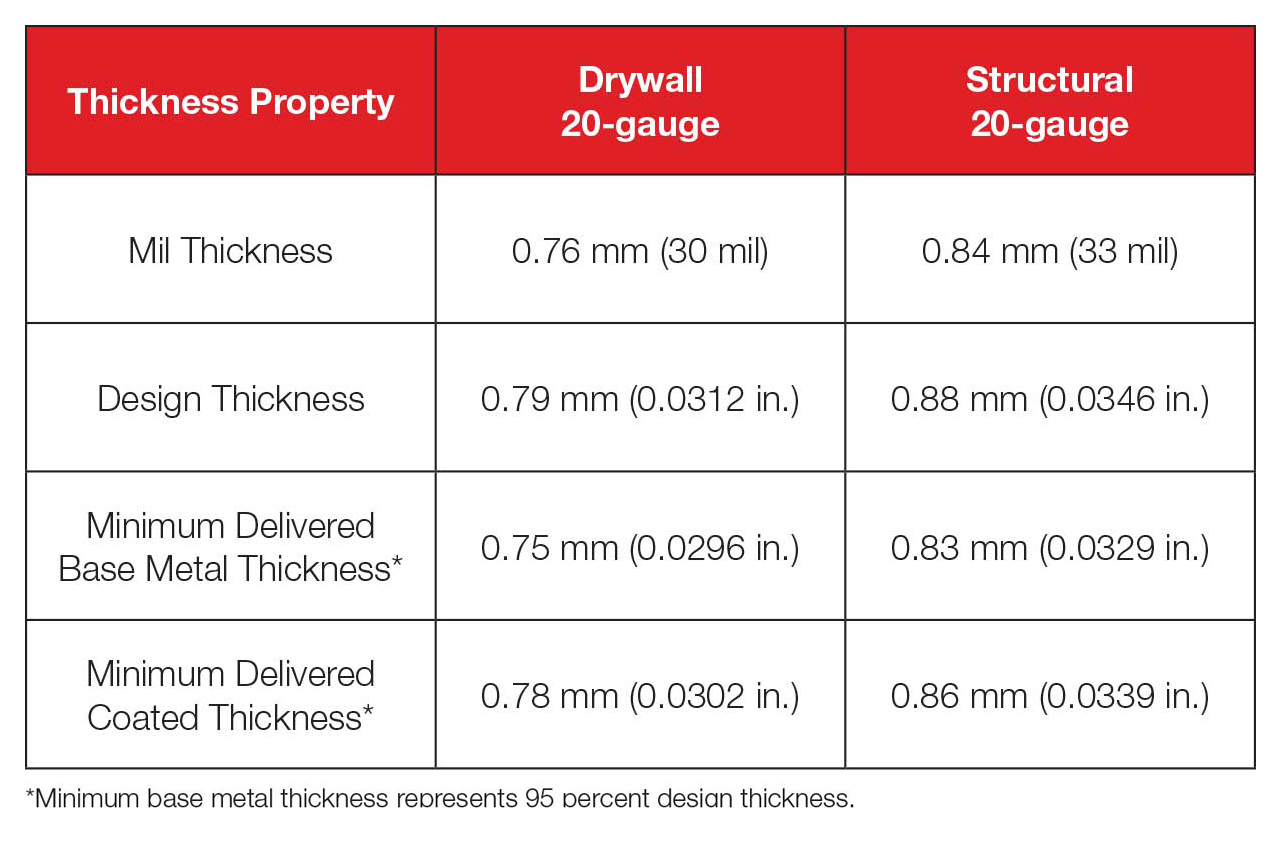

Sheet metal gauge size chart gauge or gage sizes are numbers that indicate the thickness of a piece of sheet metal with a higher number referring to a thinner sheet.

Manufacturer provide sheets thickness in gauge.

Because it is rolled at normal temperature no iron oxide scale is produced.

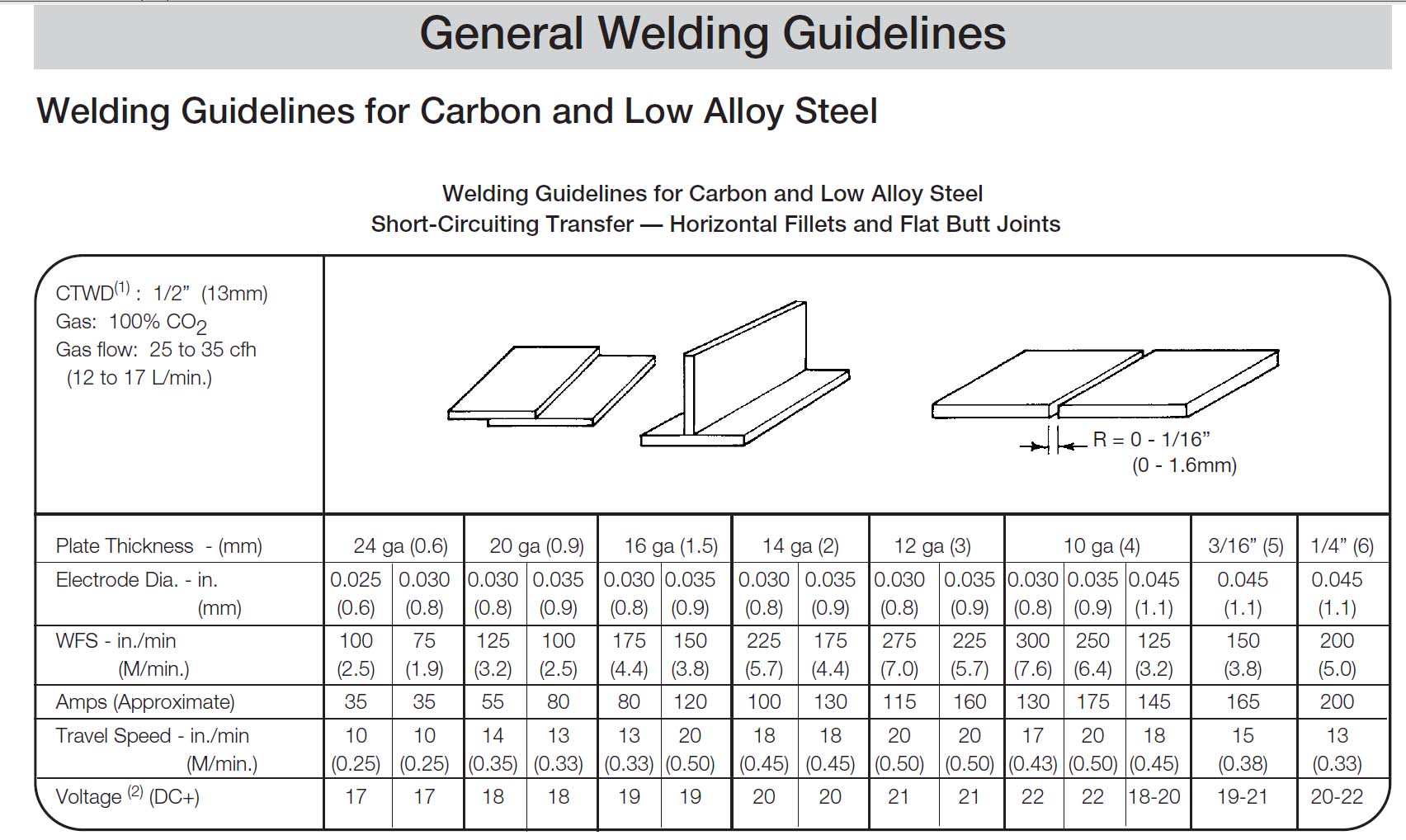

Metal thickness amperage settings.

Just as any other high traffic and high wear application the specifier needs to consider minimum thickness to avoid denting.

Sheet thickness and material selection can be done in the following ways.

It is further cold rolled from a carbon structural steel hot rolled steel strip into a steel sheet having a thickness of less than 4 mm.

I am designing a mounting bracket made of 304 stainless steel sheet of 3mm thickness.

Plain metal sheets of architectural quality vary in thickness between 025 60 mm and 124 3 mm.

A gauge conversion chart can be used to determine the actual thickness of sheet metal in inches or millimeters.

When welding mild steel a good rule of thumb is to set the amperage level at 1 amp for every 0 001 of thickness.

Extremely thin sheets are considered foil or leaf and pieces thicker than 6 mm 0 25 in are considered plate steel or structural steel.

But designers design sheet metal parts considering sheet thickness in mm.

Hi friends what is the minimum sheet metal thickness for doing a thread tapping inside a drilled hole which has to bear hanging loads.

Or is there any other way to create internal threads.

Gague are used to specify the thickness of a metal sheet.

Thicknesses can vary significantly.

So if you are welding 12 gauge mild steel with a thickness of 0 100 you would set the machine at 100 amps.